A Comprehensive Guide to DC Contactors: Understanding Their Role in Electronic Components

2025-08-06

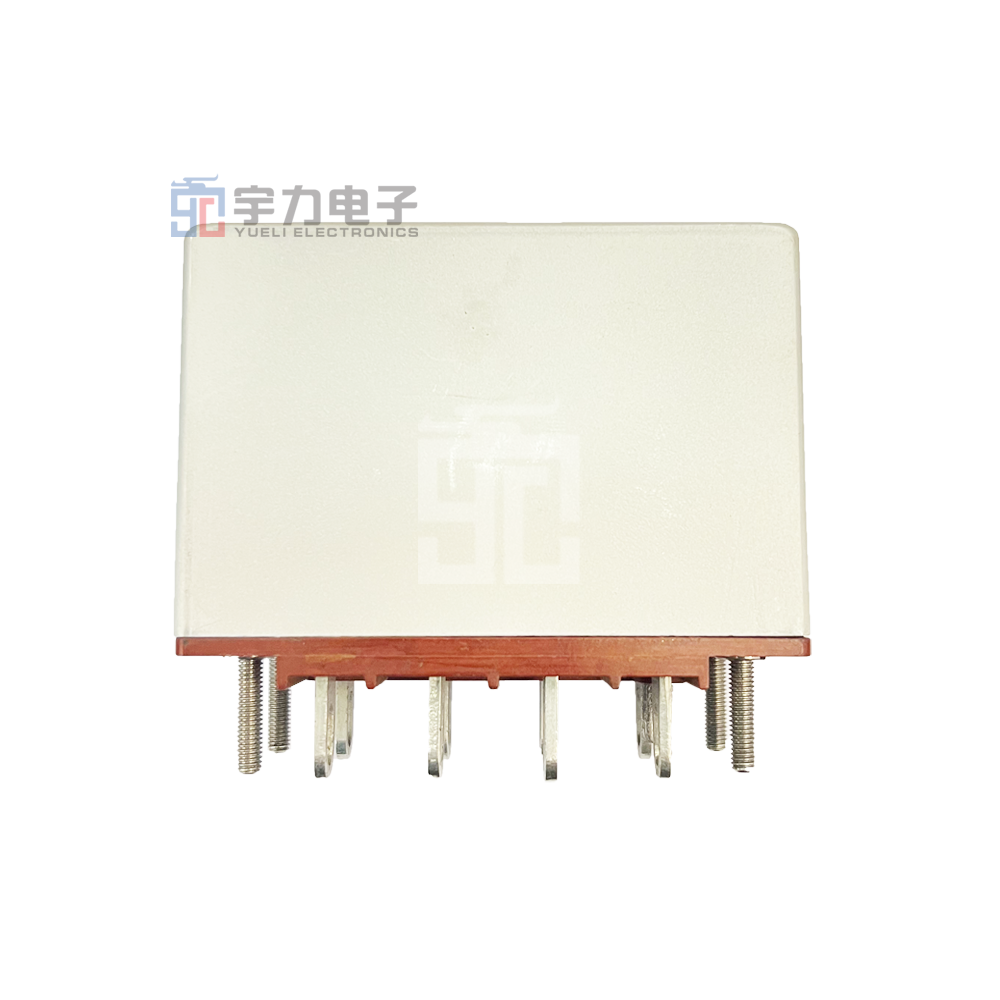

DC contactors are critical components in various electronic applications, serving as electrically controlled switches that manage the flow of direct current (DC) in circuits. They are designed to handle high current levels and are commonly used in industrial and commercial settings where reliable operation is paramount. Understanding the function and benefits of DC contactors can greatly enhance their application in electronic systems.

At its core, a DC contactor functions similarly to a relay but is specifically tailored for DC applications. The primary role of a DC contactor is to control a high-power circuit through a low-power signal. This is achieved by using an electromagnetic coil to close or open contacts, thereby allowing or interrupting the current flow. Their robust design is capable of withstanding the stress of high current and voltage, making them ideal for applications such as motor control, battery systems, and renewable energy systems.

One of the key advantages of DC contactors is their ability to provide reliable and efficient switching. Unlike their AC counterparts, DC contactors are designed to minimize arcing when the contacts open and close. This is critical because, in DC circuits, the current does not cross zero, which can lead to excessive wear on the contacts if not properly managed. Many DC contactors are equipped with features such as arc suppression to enhance longevity and performance.

In terms of applications, DC contactors are widely used in various fields. They play a crucial role in electric vehicles, where they control the power between the battery and the electric motor. In renewable energy systems, such as solar and wind power installations, DC contactors facilitate the connection between the energy source and the storage or consumption units. Furthermore, they are essential in industrial automation for controlling machinery and equipment, providing safety and efficiency in operations.

When selecting a DC contactor, it is important to consider several factors, including the operational voltage, current rating, and the environment in which they will be used. Proper selection ensures optimal performance and safety within the system. Additionally, maintenance of these components can prolong their lifespan; regular inspections and timely replacements are advisable to avoid unexpected failures.

In conclusion, understanding DC contactors is vital for anyone involved in electronic component design or application. Their role in managing DC circuits is indispensable, and their reliable performance can significantly impact the efficiency of various systems. By considering the factors discussed and selecting the right contactor for specific applications, users can optimize their electronic systems for better performance and reliability.

At its core, a DC contactor functions similarly to a relay but is specifically tailored for DC applications. The primary role of a DC contactor is to control a high-power circuit through a low-power signal. This is achieved by using an electromagnetic coil to close or open contacts, thereby allowing or interrupting the current flow. Their robust design is capable of withstanding the stress of high current and voltage, making them ideal for applications such as motor control, battery systems, and renewable energy systems.

One of the key advantages of DC contactors is their ability to provide reliable and efficient switching. Unlike their AC counterparts, DC contactors are designed to minimize arcing when the contacts open and close. This is critical because, in DC circuits, the current does not cross zero, which can lead to excessive wear on the contacts if not properly managed. Many DC contactors are equipped with features such as arc suppression to enhance longevity and performance.

In terms of applications, DC contactors are widely used in various fields. They play a crucial role in electric vehicles, where they control the power between the battery and the electric motor. In renewable energy systems, such as solar and wind power installations, DC contactors facilitate the connection between the energy source and the storage or consumption units. Furthermore, they are essential in industrial automation for controlling machinery and equipment, providing safety and efficiency in operations.

When selecting a DC contactor, it is important to consider several factors, including the operational voltage, current rating, and the environment in which they will be used. Proper selection ensures optimal performance and safety within the system. Additionally, maintenance of these components can prolong their lifespan; regular inspections and timely replacements are advisable to avoid unexpected failures.

In conclusion, understanding DC contactors is vital for anyone involved in electronic component design or application. Their role in managing DC circuits is indispensable, and their reliable performance can significantly impact the efficiency of various systems. By considering the factors discussed and selecting the right contactor for specific applications, users can optimize their electronic systems for better performance and reliability.