Three Phase Contactor: Key Features You Should Know for Efficient Electrical Control

2025-05-25

Three Phase Contactor: Key Features You Should Know for Efficient Electrical Control

Table of Contents

- 1. Introduction to Three Phase Contactors

- 2. What is a Three Phase Contactor?

- 3. Key Features of Three Phase Contactors

- 3.1 High Current Capacity

- 3.2 Reliable Switching Mechanism

- 3.3 Thermal Overload Protection

- 3.4 Compact Design and Easy Installation

- 3.5 Long Life and Durability

- 4. Applications of Three Phase Contactors

- 5. Importance of Choosing the Right Contactor

- 6. Maintenance and Care Tips for Longevity

- 7. Common Issues and Troubleshooting

- 8. Conclusion

- 9. FAQs about Three Phase Contactors

1. Introduction to Three Phase Contactors

In the realm of industrial and commercial electrical systems, three-phase contactors play a pivotal role in controlling large electrical loads. These devices are essential for the safe and efficient operation of various equipment, including motors, pumps, and other machinery that require significant power. Understanding the key features of three-phase contactors can significantly enhance your decision-making process when it comes to selecting the right components for your electrical system.

2. What is a Three Phase Contactor?

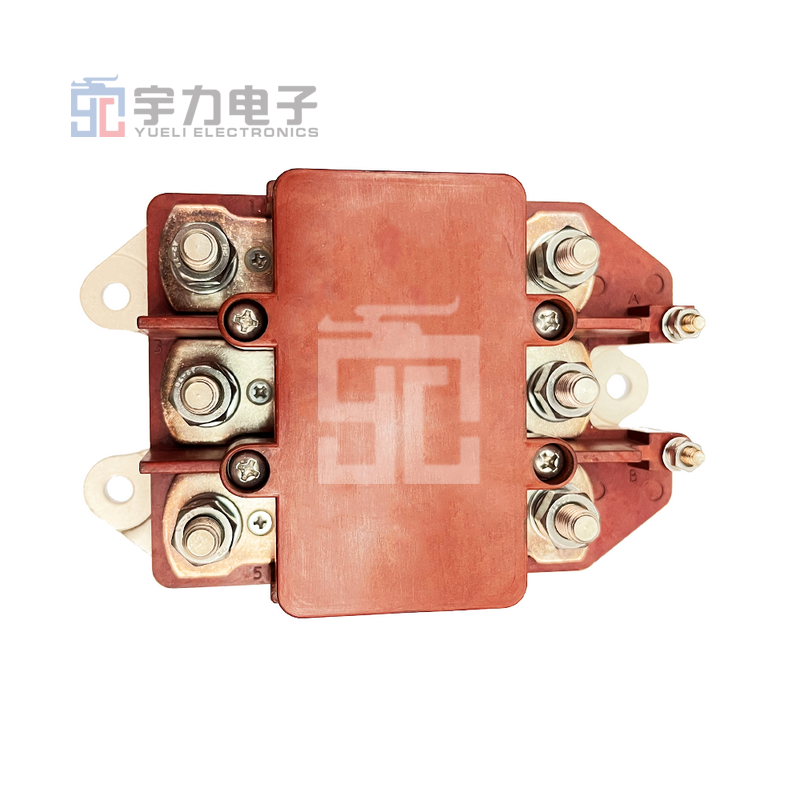

A **three-phase contactor** is an electromechanical switch used to control electrical circuits by making or breaking connections in a three-phase power supply. It consists of an electromagnetic coil and a set of contacts that close or open when the coil is energized or de-energized. This allows for the control of high voltage and current loads without requiring direct manual intervention.

Three-phase contactors are commonly used in conjunction with other devices, such as overload relays and timers, to provide a complete control solution for complex electrical systems. Their design and functionality are tailored to handle the unique demands of three-phase power, ensuring reliability and performance.

3. Key Features of Three Phase Contactors

Understanding the **key features** of three-phase contactors is essential for selecting the right model for your application. Below, we explore some of the most important characteristics that make these contactors indispensable in industrial settings.

3.1 High Current Capacity

One of the primary features of a three-phase contactor is its ability to handle **high current loads**. Depending on the application, contactors can be rated for various current levels, ensuring they can manage the demands of heavy machinery and equipment. This capability is crucial for preventing overheating and ensuring safe operation, allowing for seamless control of substantial electrical loads.

3.2 Reliable Switching Mechanism

Three-phase contactors utilize a **reliable switching mechanism**, ensuring that connections are made and broken quickly and efficiently. This rapid operation minimizes the risk of electrical arcing, which can lead to equipment damage and safety hazards. The electromagnetic coil, when energized, pulls in the contacts with precision, providing consistent performance in demanding environments.

3.3 Thermal Overload Protection

To enhance safety, many three-phase contactors come equipped with **thermal overload protection** features. This mechanism automatically disconnects the circuit when excessive current is detected, thus protecting the equipment from damage due to overheating. This built-in safeguard is critical for maintaining the longevity of motors and other connected devices.

3.4 Compact Design and Easy Installation

Modern three-phase contactors often feature a **compact design**, allowing for easier installation in tight spaces. Their user-friendly installation process requires minimal tools, making them accessible for electrical professionals and DIY enthusiasts alike. The design focuses on maximizing functionality while minimizing the footprint, which is particularly beneficial in industrial settings where space is at a premium.

3.5 Long Life and Durability

Durability is a cornerstone of three-phase contactor design. Constructed from high-quality materials, these devices are built to withstand harsh environmental conditions, including extreme temperatures and humidity. With proper maintenance, a three-phase contactor can provide **long-lasting performance**, significantly reducing the need for frequent replacements and repairs.

4. Applications of Three Phase Contactors

Three-phase contactors find extensive applications across various industries. Their versatility makes them suitable for a wide range of environments, including:

- **Industrial Automation**: Used in assembly lines and manufacturing equipment, three-phase contactors control machinery such as conveyor belts and robotic arms.

- **HVAC Systems**: They manage compressors and pumps in heating, ventilation, and air conditioning systems, ensuring efficient climate control.

- **Water Treatment Facilities**: Contactors control pumps and motors that are essential for water supply and treatment processes, maintaining operational efficiency.

- **Mining and Construction**: Heavy machinery in these industries relies on three-phase contactors for reliable power management, ensuring safety and productivity.

5. Importance of Choosing the Right Contactor

Selecting the appropriate three-phase contactor is crucial for optimizing performance and ensuring safety. Factors to consider include:

- **Voltage Rating**: Ensure the contactor can handle the voltage levels of your electrical system.

- **Current Rating**: Choose a contactor that meets or exceeds the current requirements of the connected load.

- **Environmental Considerations**: If the contactor will be used in a harsh environment, opt for a model with protective features against dust, moisture, and extreme temperatures.

By carefully evaluating these factors, you can make informed decisions that lead to enhanced efficiency and reduced operational risks.

6. Maintenance and Care Tips for Longevity

To maximize the lifespan and performance of three-phase contactors, regular maintenance is essential. Here are some practical tips:

- **Regular Inspections**: Conduct routine checks to identify any signs of wear or damage, particularly in the contacts and coil.

- **Cleaning**: Remove dust and debris from the contactor to prevent electrical interference and overheating.

- **Tightening Connections**: Ensure that all electrical connections are secure to prevent arcing and equipment failures.

- **Lubrication**: Apply appropriate lubricants to moving parts to maintain smooth operation and reduce friction.

Following these maintenance practices will help ensure your three-phase contactors operate optimally for years to come.

7. Common Issues and Troubleshooting

Despite their reliability, three-phase contactors can experience issues. Here are some common problems and their potential solutions:

- **Contact Welding**: If contacts are welded together, it may indicate excessive current or voltage spikes. Inspect the load and consider upgrading to a contactor with a higher rating.

- **Temperature Increases**: An increase in temperature can signal poor ventilation or inadequate ratings. Verify the installation environment and reevaluate the contactor specifications.

- **Frequent Trip**: If the contactor frequently trips, it may be caused by overloads or short circuits. Analyze the connected load and inspect the wiring for faults.

Quickly addressing these issues can prevent further damage and ensure the continuous operation of your systems.

8. Conclusion

Three-phase contactors are integral components in the control of high-power electrical systems across various industries. Understanding their key features—including high current capacity, reliable switching mechanisms, and thermal overload protection—enables you to make informed choices that enhance the efficiency and safety of your operations. By choosing the right contactor and implementing regular maintenance practices, you can ensure a long service life and optimal performance for your electrical systems.

9. FAQs about Three Phase Contactors

**Q1: What is the difference between a single-phase and a three-phase contactor?**

A: A single-phase contactor controls single-phase electrical circuits, while a three-phase contactor is designed for three-phase power systems, handling greater load capacities and providing smoother operation for heavy machinery.

**Q2: How do I select the right size of a three-phase contactor?**

A: To select the right size, consider the voltage and current ratings of your application, ensuring the contactor can handle the maximum load without overheating.

**Q3: Can three-phase contactors be used in residential applications?**

A: While primarily used in industrial settings, three-phase contactors can also be used in larger residential systems that require significant power, such as HVAC or large motor applications.

**Q4: What maintenance is required for three-phase contactors?**

A: Regular inspections, cleaning, tightening connections, and lubrication are essential for maintaining the performance and longevity of three-phase contactors.

**Q5: How can I troubleshoot a malfunctioning three-phase contactor?**

A: Check for signs of wear, inspect electrical connections, analyze the load requirements, and verify that the contactor's voltage and current ratings match your application. If issues persist, consult a professional electrician.