Electromagnetic Relays vs. Electromechanical: Key Differences Explained

2025-05-29

Electromagnetic Relays vs. Electromechanical: Key Differences Explained

In the realm of electrical engineering, the terms “electromagnetic relays” and “electromechanical relays” often pop up. While these components serve similar functions in circuit control, their operational mechanisms and applications differ significantly. In this article, we will explore these two types of relays in detail, offering insights into their key differences, advantages, disadvantages, and applications in various industries.

Table of Contents

- Understanding Relays: An Overview

- What Are Electromagnetic Relays?

- What Are Electromechanical Relays?

- Key Differences Between Electromagnetic and Electromechanical Relays

- Advantages of Electromagnetic Relays

- Advantages of Electromechanical Relays

- Applications of Relays in Different Industries

- Frequently Asked Questions

- Conclusion

Understanding Relays: An Overview

Relays are essential components in electrical circuits, acting as switches that control the flow of electricity. They operate by opening or closing circuits in response to an electrical signal. Relays can be categorized into various types based on their operational mechanisms, including electromagnetic and electromechanical relays. Understanding the fundamental principles of these relays is crucial for making informed decisions in circuit design and applications.

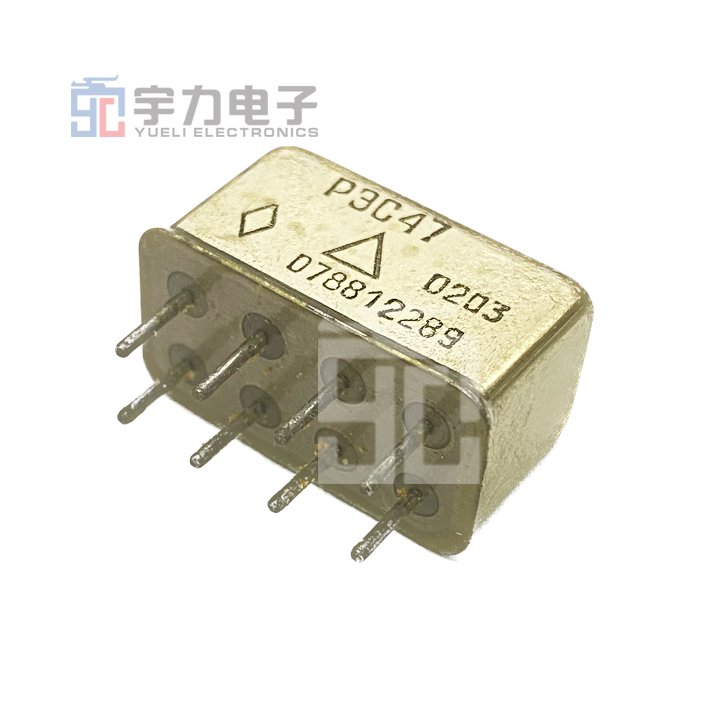

What Are Electromagnetic Relays?

Electromagnetic relays are devices that use an electromagnet to mechanically operate a switching mechanism. When an electric current flows through the coil of the relay, it generates a magnetic field that pulls a lever or armature, closing or opening the contacts in the relay. This type of relay is widely used due to its reliability and effectiveness in controlling high voltage or current loads with a lower voltage signal.

Key Components of Electromagnetic Relays

The primary components of an electromagnetic relay include:

- Electromagnet: The coil through which current flows to create a magnetic field.

- Armature: A movable lever that is attracted to the electromagnet when energized.

- Contacts: The conductive elements that open or close the circuit.

- Spring: A component that returns the armature to its original position when the current is off.

What Are Electromechanical Relays?

Electromechanical relays are similar to electromagnetic relays but often include additional mechanical components to enhance their functionality. These relays utilize both electrical and mechanical principles to perform their switching operations. They can switch multiple circuits simultaneously, allowing for more complex control scenarios.

Key Components of Electromechanical Relays

Electromechanical relays typically consist of the following parts:

- Coil: Generates the magnetic field to actuate the relay.

- Mechanical Linkage: Connects the armature to the contacts, allowing for multiple operations.

- Contacts: Function similarly to those in electromagnetic relays but can switch more complex configurations.

- Enclosure: Protects internal components from environmental factors.

Key Differences Between Electromagnetic and Electromechanical Relays

While both electromagnetic and electromechanical relays serve similar purposes, several key differences set them apart:

1. Operational Mechanism

Electromagnetic relays rely solely on electromagnetic forces to operate, while electromechanical relays integrate mechanical components that allow for more complex operations.

2. Contact Configuration

Electromechanical relays often have multiple contacts and can switch several circuits at once, whereas electromagnetic relays typically feature a simpler configuration.

3. Speed of Operation

Electromagnetic relays generally operate faster than traditional electromechanical relays, making them ideal for applications requiring quick switching.

4. Size and Weight

Electromagnetic relays are often smaller and lighter due to their design, while electromechanical relays tend to be bulkier due to additional mechanical components.

5. Applications

While both types of relays can be used in various applications, electromagnetic relays are often preferred for simple on/off switching tasks, while electromechanical relays are favored in more complex control systems.

Advantages of Electromagnetic Relays

Electromagnetic relays offer several advantages, including:

- Fast Operation: They provide quick switching capabilities, making them suitable for time-sensitive applications.

- Compact Size: Their smaller design allows for easier integration into various electronic circuits and systems.

- Low Power Consumption: They typically consume less power, making them efficient for prolonged use.

Advantages of Electromechanical Relays

Electromechanical relays come with their own set of benefits, such as:

- Multiple Circuit Control: Their ability to handle multiple circuits simultaneously enhances their versatility in control applications.

- Durability: They are designed to withstand various environmental conditions, making them robust for industrial use.

- Higher Current Ratings: Electromechanical relays can handle higher current loads, making them suitable for heavy-duty applications.

Applications of Relays in Different Industries

Both electromagnetic and electromechanical relays find applications across a variety of industries:

1. Automotive Industry

Relays play a critical role in automotive systems, controlling various functions such as lighting, ignition, and power distribution.

2. Telecommunications

They are used to manage signal routing and switching in telecommunications networks, ensuring seamless communication.

3. Industrial Automation

In industrial settings, relays control machinery, automation systems, and safety devices, making them vital for operational efficiency.

4. Home Appliances

Many household appliances, including refrigerators and washing machines, rely on relays for their operational controls.

Frequently Asked Questions

1. What is the primary function of a relay?

A relay acts as a switch to control the flow of electricity in a circuit. It can turn devices on or off based on an electrical signal.

2. How do I choose between an electromagnetic and an electromechanical relay?

Choosing between the two depends on your application requirements, such as switching speed, current rating, and complexity of the circuit. Electromagnetic relays are better for simple applications, while electromechanical relays are suited for more complex systems.

3. Are electromagnetic relays more reliable than electromechanical relays?

Reliability depends on the specific application. Electromagnetic relays can be faster and more compact, but electromechanical relays are often more robust in harsh environments.

4. Can I use relays to control high voltage devices?

Yes, both electromagnetic and electromechanical relays can be used to control high voltage devices, provided they are rated for the specific voltage and current levels.

5. How do I maintain relays for optimal performance?

Regular inspection and cleaning are crucial for maintaining relays. Ensure that contact surfaces are free of debris and oxidation, and test their functionality periodically.

Conclusion

Understanding the distinctions between electromagnetic and electromechanical relays is crucial for selecting the right component for your applications. Each type offers unique advantages and is suitable for specific scenarios. By considering the operational mechanisms, advantages, and applications of each relay type, you can make informed decisions that enhance the performance and reliability of your electronic systems. Whether you need fast switching or robust multi-circuit control, knowing these key differences will serve you well in your engineering endeavors.