Troubleshooting Common Issues with Three Phase Contactors: A Comprehensive Guide

2025-06-08

Troubleshooting Common Issues with Three Phase Contactors

Table of Contents

- 1. Introduction to Three Phase Contactors

- 2. Understanding Contactors and Their Role in Electrical Systems

- 3. Common Issues with Three Phase Contactors

- 4. Step-by-Step Troubleshooting Techniques

- 5. Preventive Maintenance for Longevity

- 6. When to Call a Professional for Assistance

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Three Phase Contactors

Three phase contactors are electrical devices used for switching electrical circuits on and off in industrial and commercial applications. These devices play a critical role in controlling electrical loads, providing an efficient means of managing power distribution. In this comprehensive guide, we will explore common issues that arise with three phase contactors and provide effective troubleshooting techniques to ensure your systems operate smoothly and efficiently.

2. Understanding Contactors and Their Role in Electrical Systems

Contactors are electromechanical switches that enable or disable the flow of electricity in a circuit. They are primarily used in three phase systems due to their ability to handle high voltages and currents. Three phase contactors are designed to control larger loads such as motors, heating elements, and lighting systems.

By using a three phase contactor, you can automate the switching process, ensuring that equipment operates only when needed, thereby saving energy and reducing wear on machinery. Understanding their design and function is essential for effective troubleshooting.

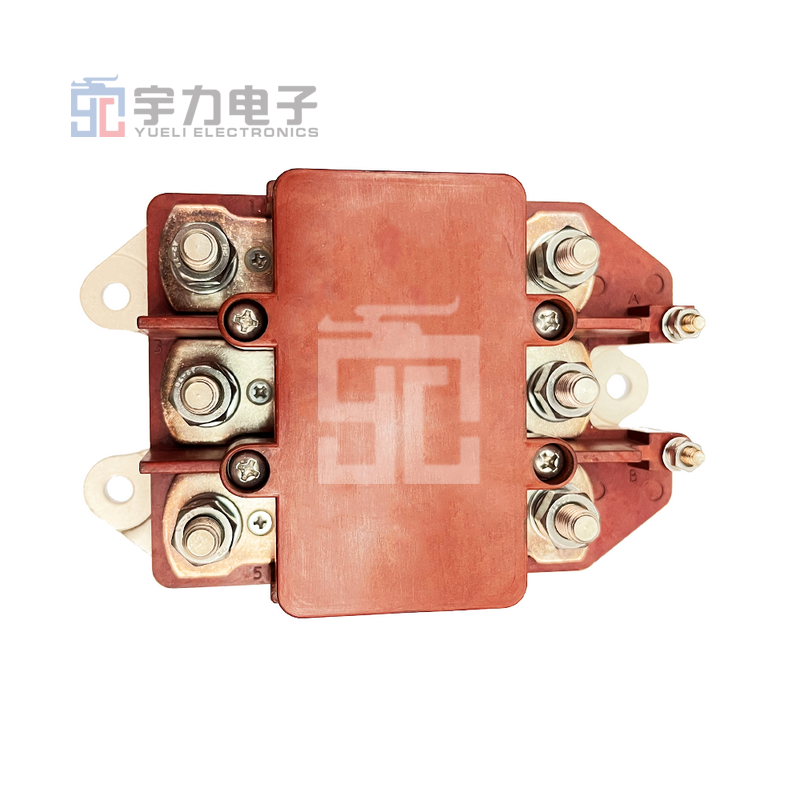

2.1 Key Components of a Three Phase Contactor

A standard three phase contactor consists of several key components:

- **Electromagnet**: This component generates a magnetic field when energized, which pulls in the armature to close the contacts.

- **Contacts**: These are the conductive pathways that complete the circuit. They can be normally open (NO) or normally closed (NC).

- **Armature**: The moving part that connects or disconnects the contacts.

- **Spring**: This returns the armature to its original position when power is removed.

- **Enclosure**: Provides protection against dust and moisture, ensuring the longevity of the device.

3. Common Issues with Three Phase Contactors

Despite their robust design, three phase contactors can experience various issues that may hinder performance. Here are some of the most common problems encountered:

3.1 Failure to Energize

One of the most common issues is the contactor failing to energize when voltage is applied. This can be due to several factors, including:

- **Open Circuit**: A broken wire or loose connection may prevent the necessary voltage from reaching the contactor.

- **Faulty Coil**: The coil may be damaged or burnt out, rendering it incapable of generating the magnetic field required to close the contacts.

- **Control Circuit Issues**: Problems within the control circuit, such as a faulty switch or relay, may also be responsible.

3.2 Overheating

Overheating is another frequent issue, often caused by:

- **Overcurrent**: Excessive load can cause the contacts to generate heat beyond their operational limits.

- **Poor Ventilation**: An enclosed environment can restrict airflow, exacerbating heat buildup.

- **Worn Contacts**: Electrical arcing can wear down contacts, leading to increased resistance and heat generation.

3.3 Contact Welding

In some cases, the contacts within the contactor may weld together, preventing them from opening and closing as intended. This often results from:

- **Surge Currents**: High inrush currents can cause welding when the contacts close.

- **Extended Use**: Continuous operation under high load can lead to material degradation.

3.4 Mechanical Wear and Tear

Mechanical failure can occur over time due to repeated use. Symptoms include:

- **Loose Armature**: Wear on the pivot points can lead to a loose or unresponsive armature.

- **Spring Fatigue**: A fatigued or broken spring may fail to return the armature to its original position.

4. Step-by-Step Troubleshooting Techniques

When faced with issues related to three phase contactors, systematic troubleshooting is essential. Follow these steps to diagnose and resolve problems effectively:

4.1 Safety First

Always prioritize safety by ensuring that the power is disconnected before inspecting or working on the contactor. Use appropriate personal protective equipment (PPE) such as gloves and safety glasses.

4.2 Visual Inspection

Start with a thorough visual check of the contactor and surrounding wiring. Look for signs of:

- Burnt connections

- Damaged insulation

- Loose terminals

4.3 Testing the Coil

Using a multimeter, check the coil resistance. This should be within the manufacturer's specified range. If it reads as an open circuit, the coil may need to be replaced.

4.4 Inspecting the Control Circuit

Verify that the control circuit is functioning correctly. Check for:

- Continuity in wiring

- Proper operation of switches and relays

- Correct voltage levels at each point in the circuit

4.5 Testing for Overheating

If overheating is suspected, measure the temperature of the contactor during operation. Additionally, ensure that the load does not exceed the contactor’s specifications.

4.6 Check Contacts and Armature

Examine the contacts for wear or damage. Use a continuity tester to ensure they open and close properly. Inspect the armature for smooth movement and proper alignment.

5. Preventive Maintenance for Longevity

Preventive maintenance is crucial to extend the life of three phase contactors. Implementing the following practices can reduce the likelihood of issues arising:

5.1 Regular Inspections

Schedule routine inspections to check for wear and tear, ensuring that any potential issues are addressed promptly.

5.2 Clean the Contactors

Dust and debris can accumulate within the contactor, leading to overheating or contact failure. Periodically clean the enclosure and components with appropriate cleaning agents.

5.3 Monitor Load Conditions

Ensure that the contactor is not subjected to loads beyond its rated capacity. Overloading can significantly reduce its lifespan.

5.4 Ensure Proper Ventilation

Maintain adequate airflow around the contactor to prevent overheating. This is especially critical in enclosed spaces.

6. When to Call a Professional for Assistance

While many issues can be resolved through DIY troubleshooting, there are times when contacting a professional is necessary:

- If you cannot identify the problem after thorough checks

- When specialized tools are needed for diagnosis

- For complex systems where safety is a concern

Engaging a qualified electrician can save time and ensure that repairs are conducted safely and effectively.

7. Frequently Asked Questions

7.1 What are the signs of a failing three phase contactor?

Common signs include failure to energize, overheating, unusual noises, and physical damage to contacts.

7.2 How can I prevent contact welding in three phase contactors?

Implementing soft-start circuits and ensuring the load does not exceed the rated capacity can help prevent contact welding.

7.3 What is the average lifespan of a three phase contactor?

The lifespan varies depending on usage and conditions but typically ranges from 10 to 15 years with proper maintenance.

7.4 Can I repair a faulty contactor myself?

Minor issues, such as replacing a coil or contacts, can often be repaired by skilled individuals. However, more complex problems should be handled by professionals.

7.5 How often should I perform maintenance on my contactors?

It is recommended to perform preventive maintenance at least once a year, or more frequently in high-use situations.

8. Conclusion

Understanding the common issues associated with three phase contactors and how to troubleshoot them effectively is crucial for maintaining efficient electrical systems. By implementing regular maintenance and being vigilant about potential problems, operators can minimize downtime and enhance the longevity of their contactors. Remember, safety should always be your top priority, and when in doubt, don't hesitate to seek professional help. With these insights, we hope you feel more equipped to tackle any issues that arise with your three phase contactors.

Previous: