Understanding DC Contactors: Essential Components for Your Electronic Applications

2025-06-25

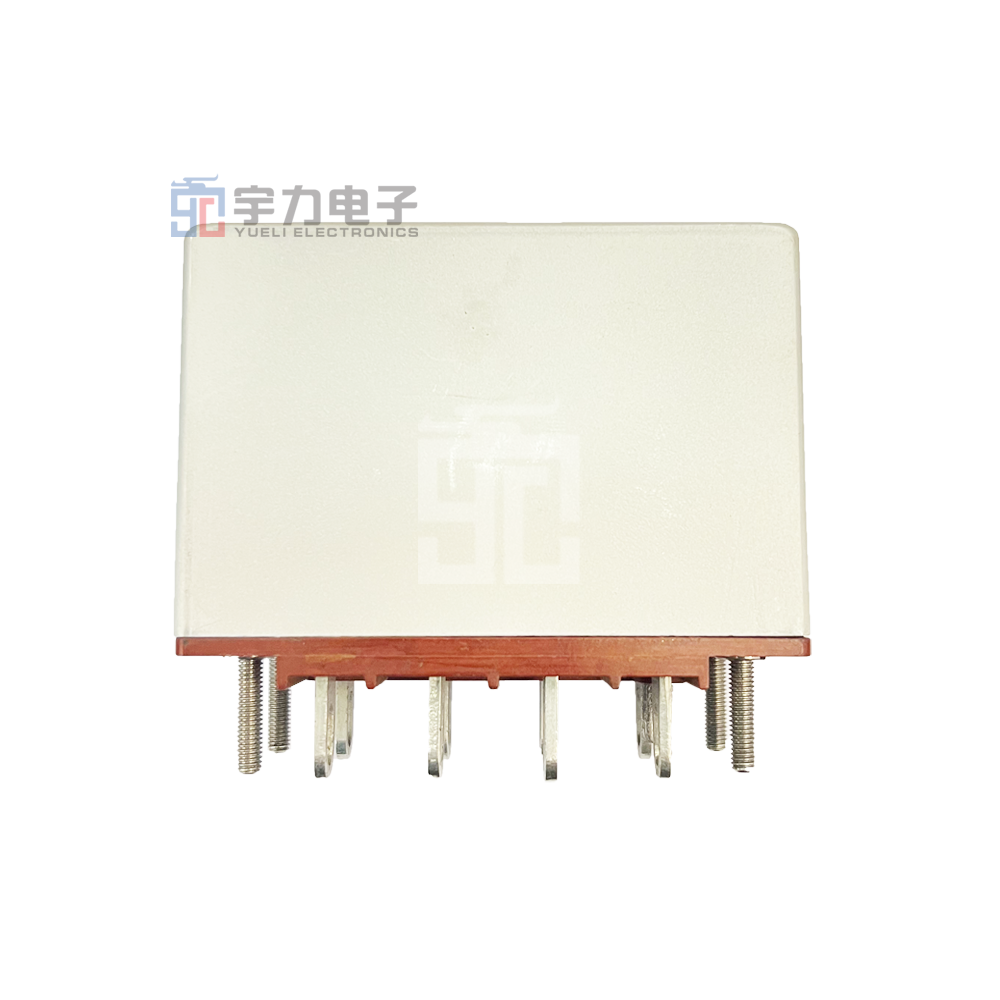

DC contactors are pivotal devices in the realm of electronic components, particularly in applications requiring the control of direct current (DC) loads. They serve as electrically operated switches that facilitate the opening and closing of circuits, enabling the effective management of power flow in various applications, including motor control, lighting systems, and renewable energy systems.

One of the primary characteristics of DC contactors is their ability to handle high current loads while providing a reliable switching mechanism. This is particularly important in applications such as electric vehicles and industrial automation, where the demand for efficient power management is essential. Unlike their AC counterparts, DC contactors need to accommodate specific challenges related to the arcing that occurs during the opening and closing of circuits. Consequently, these devices often incorporate features such as low-resistance contacts and advanced arc suppression technologies to enhance their performance and longevity.

When selecting a DC contactor, several key factors must be considered to ensure optimal performance in your specific application. These include the contactor's current and voltage ratings, the type of load being controlled (e.g., resistive or inductive), and the operational environment (e.g., temperature, humidity, and vibration). Understanding these parameters will help you choose a contactor that meets the necessary requirements for reliability and efficiency.

Additionally, the mounting style and physical dimensions of DC contactors are crucial aspects to examine, as they need to fit seamlessly into your existing systems. Many DC contactors come in various configurations, including panel-mounted and DIN rail-mounted options, allowing for versatile installation across a range of applications.

Furthermore, it's vital to consider the lifecycle and maintenance requirements of DC contactors. Regular inspections and maintenance can enhance their lifespan and performance, ensuring that your systems operate smoothly without unexpected failures. As such, investing time in understanding the operational characteristics and maintenance needs of your contactors will pay off in the long run.

In conclusion, DC contactors are indispensable components in modern electronic systems, providing essential control over direct current loads across various industries. By carefully considering their specifications, installation requirements, and maintenance practices, you can optimize the functionality of your applications and ensure long-term reliability. Embracing the potential of DC contactors will not only improve your system's efficiency but also contribute to the overall success of your projects.

One of the primary characteristics of DC contactors is their ability to handle high current loads while providing a reliable switching mechanism. This is particularly important in applications such as electric vehicles and industrial automation, where the demand for efficient power management is essential. Unlike their AC counterparts, DC contactors need to accommodate specific challenges related to the arcing that occurs during the opening and closing of circuits. Consequently, these devices often incorporate features such as low-resistance contacts and advanced arc suppression technologies to enhance their performance and longevity.

When selecting a DC contactor, several key factors must be considered to ensure optimal performance in your specific application. These include the contactor's current and voltage ratings, the type of load being controlled (e.g., resistive or inductive), and the operational environment (e.g., temperature, humidity, and vibration). Understanding these parameters will help you choose a contactor that meets the necessary requirements for reliability and efficiency.

Additionally, the mounting style and physical dimensions of DC contactors are crucial aspects to examine, as they need to fit seamlessly into your existing systems. Many DC contactors come in various configurations, including panel-mounted and DIN rail-mounted options, allowing for versatile installation across a range of applications.

Furthermore, it's vital to consider the lifecycle and maintenance requirements of DC contactors. Regular inspections and maintenance can enhance their lifespan and performance, ensuring that your systems operate smoothly without unexpected failures. As such, investing time in understanding the operational characteristics and maintenance needs of your contactors will pay off in the long run.

In conclusion, DC contactors are indispensable components in modern electronic systems, providing essential control over direct current loads across various industries. By carefully considering their specifications, installation requirements, and maintenance practices, you can optimize the functionality of your applications and ensure long-term reliability. Embracing the potential of DC contactors will not only improve your system's efficiency but also contribute to the overall success of your projects.

Previous: