Miniature Relays: An In-Depth Guide to Specifications, Types, and Applications

2025-07-26

Miniature Relays: An In-Depth Guide to Specifications, Types, and Applications

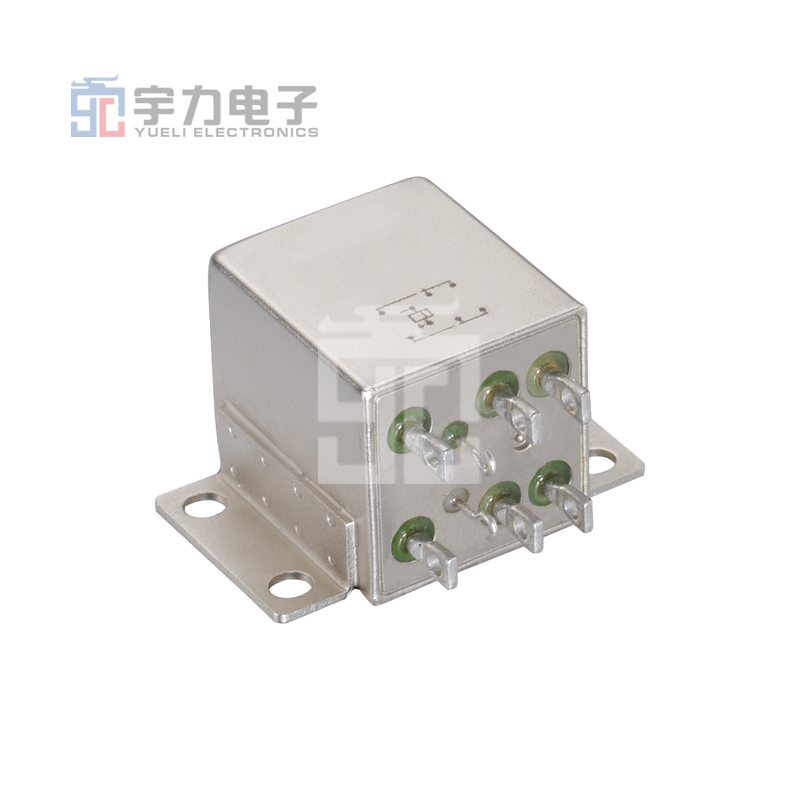

Miniature relays are critical components in various electronic devices, providing reliable control over electrical circuits. These compact switches allow for the seamless operation of machinery, automation, and control systems. As we dive deeper into the world of miniature relays, we will explore their specifications, types, applications, and tips for selecting the right relay for your specific needs.

Table of Contents

- What Are Miniature Relays?

- Specifications of Miniature Relays

- Types of Miniature Relays

- Applications of Miniature Relays

- Benefits of Using Miniature Relays

- How to Select the Right Miniature Relay

- Maintenance and Care of Miniature Relays

- FAQs about Miniature Relays

- Conclusion

What Are Miniature Relays?

Miniature relays are small electromechanical devices used for switching applications. They typically feature a low profile, making them ideal for applications where space is at a premium. These relays can control a circuit by opening and closing contacts, allowing or interrupting the flow of electricity. The primary function of miniature relays includes isolating control circuits from high voltage circuits, providing safety and reliability in various electronic systems.

Specifications of Miniature Relays

Understanding the specifications of miniature relays is essential for selecting the right component for your application. Key specifications to consider include:

Contact Configuration

Miniature relays are available in different contact configurations such as single pole single throw (SPST), single pole double throw (SPDT), and double pole double throw (DPDT). The choice of configuration depends on the specific circuit requirements.

Coil Voltage

The coil voltage rating refers to the voltage required to energize the relay. Common ratings include 5V, 12V, 24V, and 48V. Choosing the right coil voltage is critical to ensure proper relay operation.

Contact Rating

Contact ratings specify the maximum current and voltage that the relay contacts can handle. This is crucial for preventing contact failure and ensuring reliable operation. Ratings are usually expressed in terms of resistive and inductive loads.

Switching Speed

The switching speed of a miniature relay indicates how quickly it can open or close contacts. This is important in applications requiring fast response times, such as in automation and control systems.

Operating Temperature Range

Miniature relays are rated for specific operating temperature ranges to ensure they function correctly in various environmental conditions. Common ranges include -40°C to +85°C, but this can vary by manufacturer.

Types of Miniature Relays

Miniature relays come in various types, each designed for specific applications and requirements. Understanding these types will help you choose the most suitable relay for your project.

Electromechanical Relays

Electromechanical relays (EMRs) are the most common type of miniature relays. They utilize an electromagnetic coil to create a magnetic field, which moves an armature to open or close the contacts. EMRs offer excellent switching capabilities and can handle higher loads compared to other types. They are widely used in household appliances, automotive applications, and industrial control systems.

Solid State Relays

Solid state relays (SSRs) use semiconductor devices to perform switching without moving parts. This design provides several advantages, including faster switching speeds, longer lifespan, and resistance to shock and vibration. SSRs are ideal for applications in harsh environments and are commonly found in heating, lighting control, and motor control systems.

Reed Relays

Reed relays consist of two ferromagnetic contacts sealed within a glass envelope, which opens and closes in response to an external magnetic field. These relays are characterized by their compact size and low power consumption, making them suitable for low-current applications such as sensors and telecommunications equipment.

Applications of Miniature Relays

Miniature relays are utilized across various industries due to their versatility and reliability. Here are some common applications:

Automotive Industry

In the automotive sector, miniature relays are used in systems like lighting, HVAC, and power windows. They enable efficient control of various electrical components while ensuring safety and reliability.

Industrial Automation

Miniature relays play a crucial role in industrial automation, controlling motors, sensors, and safety devices. Their quick response times and durability make them ideal for factory settings.

Telecommunications

In telecommunications, miniature relays are used in switching equipment, routers, and communication devices. They provide reliable operation under varying load conditions, ensuring uninterrupted communication.

Home Appliances

Many home appliances, such as washing machines, microwaves, and refrigerators, rely on miniature relays to manage electrical components. They enhance the efficiency and safety of these devices.

Benefits of Using Miniature Relays

Choosing miniature relays offers numerous benefits, including:

Space Efficiency

As their name suggests, miniature relays are compact, allowing for efficient use of space in electronic designs. This is particularly advantageous in applications where size constraints are a concern.

Cost-Effectiveness

Miniature relays are often more affordable compared to larger relays, providing an economical solution for manufacturers and engineers looking to optimize their designs.

Reliability

These relays are designed to operate under various conditions, making them highly reliable components in electronic circuits. Their longevity helps reduce maintenance and replacement costs over time.

Versatility

Miniature relays can be used in a wide range of applications, making them a versatile choice for different industries. Their adaptability means they can meet specific needs effectively.

How to Select the Right Miniature Relay

Selecting the appropriate miniature relay involves considering several factors to ensure optimal performance in your application. Here are key considerations:

Identify Your Requirements

Determine the electrical specifications needed for your application, such as contact ratings, coil voltage, and switching speed. Understanding these parameters will guide your selection process.

Consider the Environment

Evaluate the environmental conditions where the relay will be used, including temperature, humidity, and potential exposure to contaminants. This will help you choose a relay designed to withstand those conditions.

Evaluate Load Types

Different relays handle various types of loads differently. Ensure that the relay you choose is suitable for the type of load (resistive, inductive, etc.) you will be controlling.

Look for Manufacturer Quality

Opt for relays from reputable manufacturers, as quality can significantly impact performance and reliability. Research reviews and specifications to ensure you are choosing a reliable product.

Maintenance and Care of Miniature Relays

Proper maintenance and care of miniature relays can extend their lifespan and ensure reliable operation. Here are some best practices:

Regular Inspection

Conduct regular inspections of relays to check for any signs of wear or damage. Look for signs of overheating, corrosion, or physical damage that may affect performance.

Keep Connections Clean

Ensure that all connections are clean and free from dust, dirt, or corrosion. Poor connections can lead to faulty operation and reduced relay lifespan.

Follow Usage Guidelines

Adhere to the manufacturer's specifications regarding voltage, current, and temperature limits. Overloading a relay can lead to premature failure.

FAQs about Miniature Relays

1. What is the difference between an electromechanical relay and a solid state relay?

Electromechanical relays use moving parts and electromagnetic coils to operate, whereas solid state relays use semiconductor devices without moving parts, providing faster switching and greater durability.

2. How do I determine the right coil voltage for my relay?

The right coil voltage depends on the supply voltage available in your application. Always match the relay's coil voltage rating to your power supply to ensure proper operation.

3. Can miniature relays be used in high-power applications?

While miniature relays can handle moderate power levels, for high-power applications, it's essential to select a relay with the appropriate contact ratings to ensure reliable operation.

4. How long do miniature relays typically last?

The lifespan of miniature relays varies based on usage and environmental conditions, but they can usually last anywhere from several thousand to millions of cycles if used within their specified limits.

5. What should I consider when using miniature relays in an automated system?

Consider switching speed, contact ratings, response times, and environmental conditions. Ensure that the relays are compatible with other components in the automation system for optimal performance.

Conclusion

Miniature relays are essential components that enhance the functionality and reliability of various electronic systems. By understanding their specifications, types, and applications, you can make informed decisions about which relay suits your needs best. Whether in automotive, industrial, or consumer electronics, miniature relays play a pivotal role in ensuring efficient operation. Always prioritize quality and suitability to maximize the benefits of these invaluable devices.