Understanding Sealed Relays: Key Features and Applications

2025-12-30

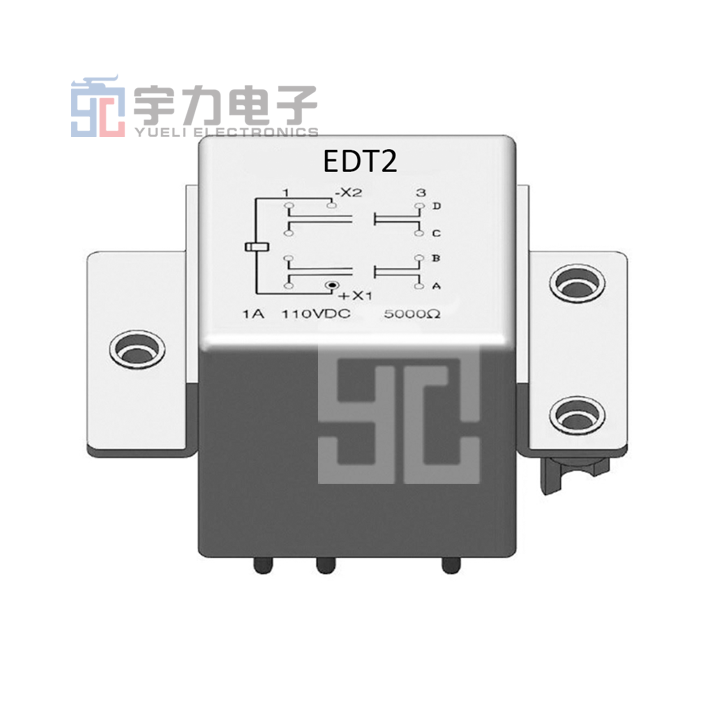

Sealed relays are specialized types of electromagnetic switches designed to operate in environments where exposure to dust, moisture, and other contaminants could compromise performance. The sealing mechanism typically employs a hermetically sealed enclosure, which protects the internal components from external elements. This attribute is particularly vital in applications requiring high reliability and durability.

One of the primary features of sealed relays is their robust construction. The hermetic seal is often achieved through welding techniques that fuse the relay's casing, ensuring that no air or contaminants can infiltrate the device. This design enables sealed relays to function effectively in harsh conditions, including industrial settings, automotive environments, and outdoor applications.

In terms of electrical performance, sealed relays exhibit several advantages. They can handle a wide range of voltage and current levels, making them versatile components in various electronic circuits. Their ability to switch high loads while maintaining low contact resistance contributes to their efficiency and longevity. Additionally, the absence of exposed contacts minimizes the risk of arcing, further enhancing their reliability.

Sealed relays are widely used across different sectors. In the automotive industry, for example, they are often employed in control systems for headlights, wipers, and other critical functions. Their resistance to environmental factors ensures consistent operation, which is crucial for safety and performance. Similarly, in industrial automation, sealed relays serve to control machinery and equipment, functioning as essential safety interlocks that protect against unexpected failures.

Another significant aspect of sealed relays is their compatibility with various mounting configurations. Whether PCB-mounted or socket-mounted, these relays can fit seamlessly into different designs, providing flexibility for engineers and designers. This adaptability, coupled with their proven reliability, makes sealed relays a preferred choice for many applications.

When selecting a sealed relay for a project, it is essential to consider factors such as the required switching capacity, operating voltage, and environmental conditions. Understanding these parameters helps ensure that the chosen relay will meet the specific demands of the application. Furthermore, investing time in proper circuit design and relay integration can significantly improve system performance and longevity.

In conclusion, sealed relays are invaluable components in the electronics landscape, offering protection against environmental factors while delivering reliable performance. Their unique features and wide-ranging applications underscore their importance in various industries, from automotive to industrial automation. As technology continues to evolve, sealed relays are likely to remain integral in ensuring that electronic systems operate reliably in challenging conditions.

One of the primary features of sealed relays is their robust construction. The hermetic seal is often achieved through welding techniques that fuse the relay's casing, ensuring that no air or contaminants can infiltrate the device. This design enables sealed relays to function effectively in harsh conditions, including industrial settings, automotive environments, and outdoor applications.

In terms of electrical performance, sealed relays exhibit several advantages. They can handle a wide range of voltage and current levels, making them versatile components in various electronic circuits. Their ability to switch high loads while maintaining low contact resistance contributes to their efficiency and longevity. Additionally, the absence of exposed contacts minimizes the risk of arcing, further enhancing their reliability.

Sealed relays are widely used across different sectors. In the automotive industry, for example, they are often employed in control systems for headlights, wipers, and other critical functions. Their resistance to environmental factors ensures consistent operation, which is crucial for safety and performance. Similarly, in industrial automation, sealed relays serve to control machinery and equipment, functioning as essential safety interlocks that protect against unexpected failures.

Another significant aspect of sealed relays is their compatibility with various mounting configurations. Whether PCB-mounted or socket-mounted, these relays can fit seamlessly into different designs, providing flexibility for engineers and designers. This adaptability, coupled with their proven reliability, makes sealed relays a preferred choice for many applications.

When selecting a sealed relay for a project, it is essential to consider factors such as the required switching capacity, operating voltage, and environmental conditions. Understanding these parameters helps ensure that the chosen relay will meet the specific demands of the application. Furthermore, investing time in proper circuit design and relay integration can significantly improve system performance and longevity.

In conclusion, sealed relays are invaluable components in the electronics landscape, offering protection against environmental factors while delivering reliable performance. Their unique features and wide-ranging applications underscore their importance in various industries, from automotive to industrial automation. As technology continues to evolve, sealed relays are likely to remain integral in ensuring that electronic systems operate reliably in challenging conditions.

Previous: