Three Phase Contactor vs. Single Phase: Which is Better for Your Needs?

2025-07-20

Three Phase Contactor vs. Single Phase: Which is Better for Your Needs?

Table of Contents

- Understanding Contactors: An Overview

- The Difference Between Single Phase and Three Phase Contactors

- Advantages of Three Phase Contactors

- Advantages of Single Phase Contactors

- Disadvantages of Three Phase Contactors

- Disadvantages of Single Phase Contactors

- Applications of Three Phase Contactors

- Applications of Single Phase Contactors

- Making the Right Choice: Factors to Consider

- Frequently Asked Questions (FAQs)

- Conclusion: Your Best Option

Understanding Contactors: An Overview

Contactors are crucial components in electrical circuits, serving as a switch to control the flow of electricity. They can handle high voltage and current loads, making them essential for various industrial and commercial applications. Understanding the different types of contactors is vital for selecting the right one for your needs.

The Difference Between Single Phase and Three Phase Contactors

Single-phase contactors are designed for circuits that use a single alternating current (AC) phase. They are commonly used in residential settings and small electrical devices. On the other hand, three-phase contactors work with three alternating current phases, providing a more efficient power distribution system. They are often utilized in larger industrial applications.

Single Phase Contactors

Single-phase contactors typically feature two or three poles and are suited for lower power applications, usually up to 30 amps. They are ideal for controlling equipment like small motors, lighting systems, and heating appliances.

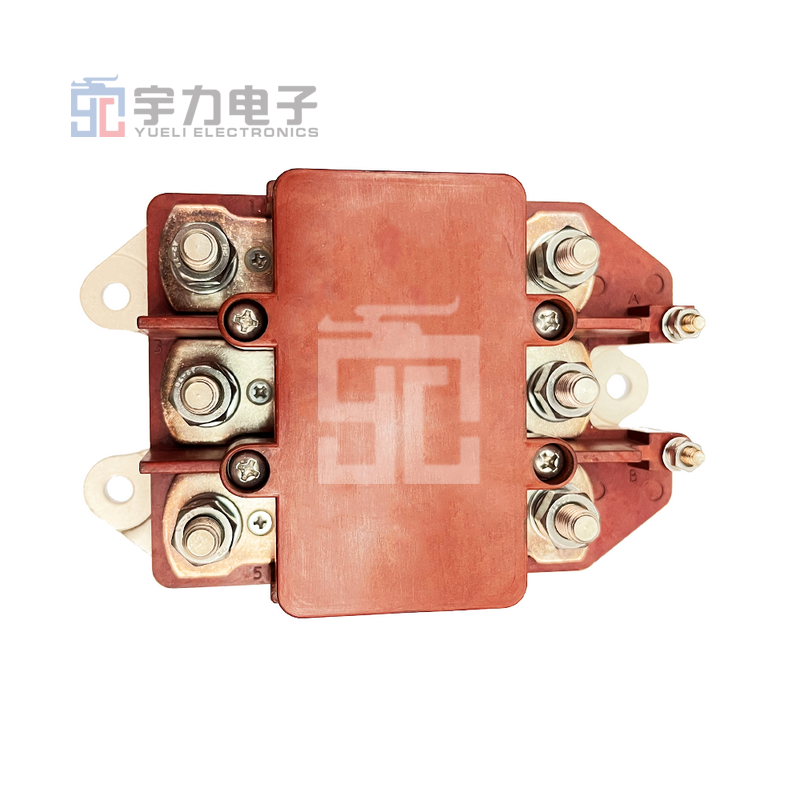

Three Phase Contactors

In contrast, three-phase contactors are built to manage higher electrical loads, often exceeding 30 amps. They have three or four poles, allowing them to control three-phase motors, large machinery, and heavy industrial equipment.

Advantages of Three Phase Contactors

Three-phase contactors offer several key advantages:

1. Higher Efficiency

Three-phase systems provide a more balanced power load, resulting in less energy loss. This efficiency is particularly beneficial in industrial applications where large machinery operates continuously.

2. Greater Stability

With three-phase contactors, the power supply remains stable under heavy loads. This stability reduces the risk of equipment failure and extends the lifespan of electrical devices.

3. Reduced Motor Size

Three-phase motors can produce the same power output as single-phase motors while being smaller and lighter. This benefit allows for more compact machine designs without sacrificing performance.

Advantages of Single Phase Contactors

Single-phase contactors also have their strengths:

1. Simplicity and Cost-Effectiveness

Single-phase systems are generally simpler and less expensive to install. This makes them ideal for residential applications where complex systems are unnecessary.

2. Ease of Use

Single-phase contactors are easier to operate and maintain. They are perfect for small-scale operations and DIY projects, making them accessible for non-professionals.

3. Adequate for Lower Power Needs

For applications that do not require high power, single-phase contactors are perfectly adequate. They can efficiently control lights, fans, and small appliances without incurring unnecessary costs.

Disadvantages of Three Phase Contactors

While three-phase contactors have many advantages, they also come with certain drawbacks:

1. Higher Initial Cost

The initial investment for three-phase contactors can be significantly higher than their single-phase counterparts. This cost may not be justified for smaller applications.

2. Complex Installation Requirements

Three-phase systems often require more complex wiring and installation. This complexity can lead to increased installation costs and may necessitate professional assistance.

3. Not Suitable for Low-Power Applications

For small appliances or residential needs, three-phase contactors may be overkill, providing unnecessary power and complexity.

Disadvantages of Single Phase Contactors

Single-phase contactors are not without their limitations:

1. Lower Efficiency

Single-phase systems can experience power loss due to imbalances in the load. This inefficiency can lead to increased energy costs over time.

2. Limited Power Capacity

Single-phase contactors are unsuitable for high-power applications. They cannot effectively control large motors or heavy machinery demands.

3. Risk of Overloading

Because single-phase systems are designed for lower loads, using them for higher-demand applications can lead to overheating and potential equipment failure.

Applications of Three Phase Contactors

Three-phase contactors are commonly found in various industrial settings. Their applications include:

1. Industrial Machinery

Three-phase contactors are essential for controlling large motors and complex machinery in manufacturing environments.

2. HVAC Systems

These contactors are used in heating, ventilation, and air conditioning systems to efficiently manage power distribution and ensure stable operation.

3. Water and Wastewater Treatment

In water treatment facilities, three-phase contactors help control the motors that drive pumps and other equipment.

Applications of Single Phase Contactors

Single-phase contactors find their place in various residential and light commercial applications:

1. Residential Wiring

They are commonly used in homes for controlling lighting, fans, and small appliances.

2. Small Motors

Single-phase contactors effectively manage small electric motors in tools, pumps, and other equipment.

3. Home Heating Systems

They are often utilized in electric heating systems to switch on and off various heating appliances.

Making the Right Choice: Factors to Consider

When choosing between a three-phase and single-phase contactor, consider the following factors:

1. Power Requirements

Identify the power demands of the equipment you intend to control. If your machinery requires significant power, three-phase contactors may be more suitable.

2. Budget Constraints

Evaluate your budget for the initial investment and ongoing operational costs. Determine whether the cost-benefit ratio of a three-phase system justifies its purchase.

3. Space Availability

Consider the physical space available for installation. If you have limited space, a single-phase system may offer a more compact and practical solution.

4. Future Growth

Anticipate any potential future expansion of your operations. If you plan to increase power needs or add more heavy machinery, a three-phase system could provide the necessary flexibility.

Frequently Asked Questions (FAQs)

1. What is a contactor?

A contactor is an electrically controlled switch used to control power circuits, capable of handling high voltage and current loads.

2. How do I know if I need a single-phase or three-phase contactor?

Assess your power requirements. If your application involves lower power, a single-phase contactor is adequate. For heavier machinery and industrial applications, a three-phase contactor is more suitable.

3. Can I use a three-phase contactor for a single-phase application?

Yes, you can use a three-phase contactor for single-phase applications, but it may be more costly and complex than necessary.

4. Are single-phase contactors less reliable than three-phase contactors?

Not necessarily. Both types can be reliable; however, three-phase contactors provide increased stability and efficiency for larger applications.

5. What maintenance is required for contactors?

Regular inspections, cleaning, and testing of the contacts and coils are necessary to ensure optimal performance and longevity.

Conclusion: Your Best Option

When deciding between a three-phase contactor and a single-phase contactor, it's essential to consider your specific needs, including power requirements, budget, and application type. While three-phase contactors excel in efficiency and stability, single-phase contactors offer simplicity and lower initial costs. By carefully evaluating your circumstances, you can make an informed decision that best suits your operational needs, ensuring optimal performance and reliability for your electrical systems.

Previous: